Have you noticed your PWC feeling a bit shaky when you try to take off? Or it feels like it wants to go, but doesn’t?

Well, that could be due to a common issue known as cavitation. I notice that sometimes, people mistake it for “slipping gears.”

Let me explain what it is and why it might be causing these problems for your PWC below.

Cavitation Explained — And How It Affects Your PWC?

Cavitation effects boats with impellers or props and is fascinating.

It occurs when water pressure drops below vapor pressure, forming bubbles that implode, not explode.

These implosions erode the impeller, which makes it get worse.

It’s everywhere, not limited to boats. Watch this video below to learn more:

Watercraft Shakes And won’t Go?

You’ll know your watercraft is having cavitation issues when you give it gas, and it doesn’t want to go.

Many people mistake it for “slipping gears” or a slow take-off.

The jet ski make eventually catch, and you can reach top speed, but it takes forever as it feels like the jet ski is “spinning its wheel’s”.

The Reasons You’re Experiencing Cavitation

Cavitation damage often results from sucking up debris such as rocks, sticks, ropes, and even unusual items like snakes (yes, it’s happened to me).

It can also stem from manufacturer defects or worn-out parts like a bent driveshaft, causing impeller imbalance.

In most cases I’ve seen, it’s due to sucking something up and damaging the wear ring and impeller.

The Step-By-Step Solution

Since the most common reason for cavitation is something was sucked up, you will need to remove the item that was sucked up and repair the damage.

Steps:

- Get the jet ski out of the water and on a trailer or stand.

- Secure it so it doesn’t move and have the engine off.

- Look into the intake grate to see if you can see anything out of the ordinary.

- Look at the rear into the pump to see if you can see anything.

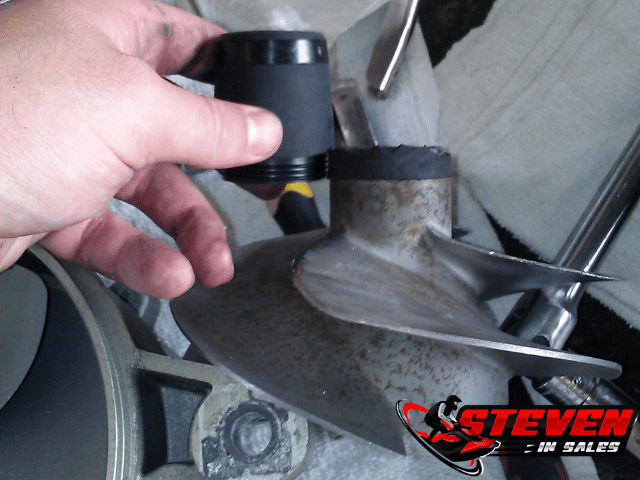

- Remove the jet pump to fully see if any debris is hiding or stuck – best to let the repair shop do this. A lot of the debris won’t be easy to spot unless the jet pump is removed.

You need to inspect what is stuck in the impeller and assess the damage.

If the wear ring or impeller are damaged, the jet pump must be removed and these items repaired.

It’s advisable to have the local repair shop handle it for you, as you may require a special impeller removal tool, and wear rings on some models can be tricky to work with.

Note: You CAN NOT get to the jet pump from the inside of your machine, the pump is on the outside!!! I've had several people start to rip their engine apart to get to the pump, and it only makes things worse for themselves.

The Easy Fixes

Sometimes it can be an easy fix of simply knocking the rocks loose, as it may have not done enough damage to cause constant cavitation.

Other times, rocks can cause significant damage, necessitating the replacement of the impeller and/or wear ring.

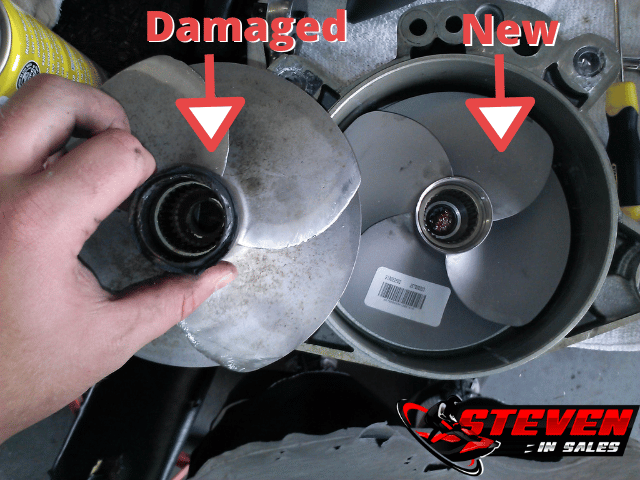

If you observe cuts or a generally non-smooth impeller, replacement is necessary.

Even “slight barbs” and cuts will cause it to cavitate.

But There Is Nothing In The Pump?!

It is possible to take out the jet pump and notice nothing be stuck in it, but damage was still done.

Often, it only damages the wear ring, which is what it is designed to do. Jet skis are powerful, so the item that was once stuck is now blown out, but the damage has been done and it cavitates.

Is This a Routine Maintenance Item?

An impeller is always experiencing some kind of cavitation, but the manufacturer designs it so that it’s so small it’s not an issue.

The only time it can become an issue is if you suck something up or the jet pump is damaged.

There are the few times something in the jet pump or connected to the jet pump fails and starts cavitating, but from my years in the field, the most often it’s because of someone sucking something up.

The Estimated Costs To Fix?

The repair cost varies based on the damage, ranging from $100 to $1,000 or more, depending on what needs fixing and your machine’s type.

DIY is an option, particularly for models like the Sea-Doo Spark without iBR, which is straightforward. Some models may be more challenging but still manageable.

Proper tightening and alignment are crucial to prevent issues. Failure to tighten the proper bolt in the jet pump area correctly can cause some PWCs to sink.

Sucking Things Up Is Not Covered Under Warranty

Unless it was a manufacturer defect, it won’t be covered under warranty. Let me be blunt: it’s usually not a manufacturer defect, so don’t expect warranty coverage to help.

The cavitation that most PWCs experience is often done by someone sucking something up, so it’s NOT a warranty item.

You need to be careful while operating in shallow water, as covered in this post.

Hey Steve. Have a 2016 3up Spark purchased used in 2022. It has gone through 3 wear rings in under 20 hours of use all in the Parry Sound area of Georgian Bay which I think is fairly “clean” water. The first time was in a very weedy bay but the other 2 were while cruising open water. Is this common for the Spark model ? Seems to blow a hole in the side of the wear ring almost too easily. Getting frustrated with this so very seriously considering the stainless ring. Thanks for any advice.

This is not normal, and I would check the pump and bearings to make sure there is not too much wobble or something else is causing it to fail that quickly. If you can’t find anything, then moving to the stainless steel will be the next best option.