Ever wondered what makes PWC and jet boats move? Well, they both rely on something called a “jet-pump” for propulsion, which sets them apart from regular boats with traditional propellers.

So, what’s this pump all about?

It’s an interesting system that includes a steering nozzle, which lets you control the left-right movement, a reverse bucket for handling forward, reverse, and even braking, and if you’re feeling fancy, there’s also the option for trim control.

Now, let’s dive deeper into the details and bust some common myths about them in this post below!

The heart of a jet pump is the impeller, which closely resembles a propeller, with only slight differences.

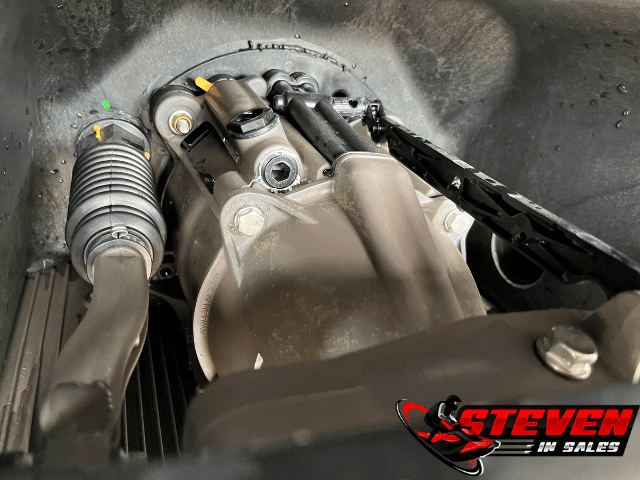

Impeller – Wear Ring – Cables

The impeller, enclosed by a wear ring with tight tolerances, can wear out if debris is sucked up. The wear ring serves to protect the jet pump.

A damaged wear ring can cause cavitation and performance issues.

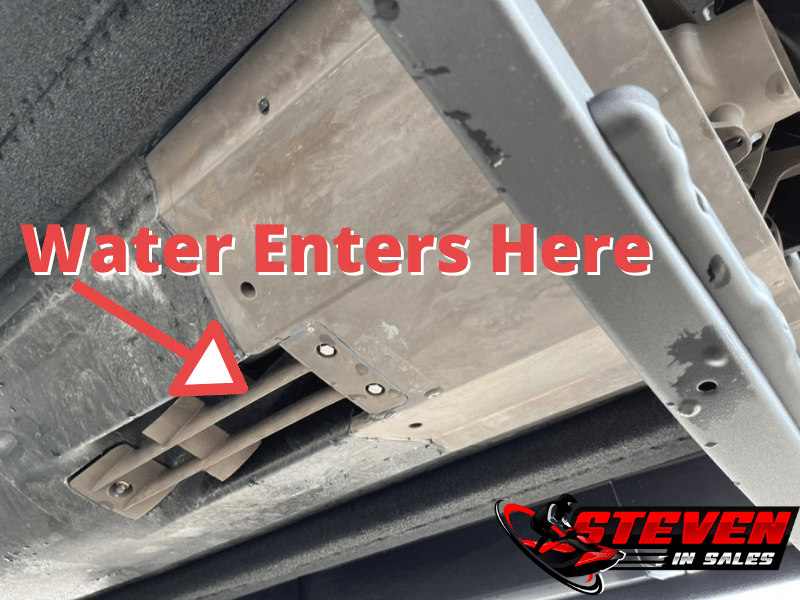

The pump housing connects to the hull, which has cable holes and water-suction (bailer tubes) openings driven by the pump’s suction.

Direct Drive = When The Engine is On, It’s Moving

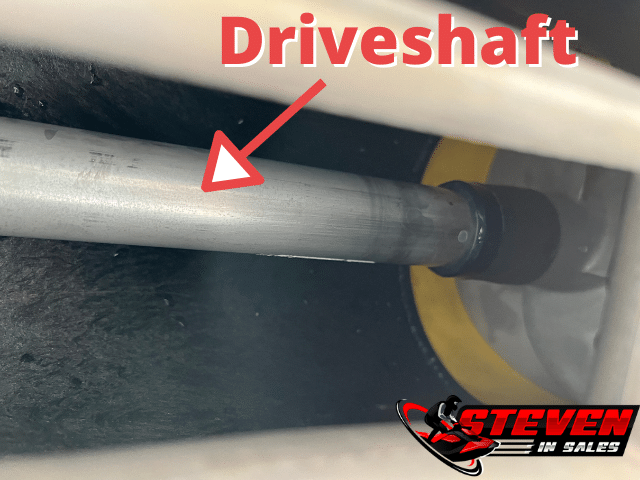

The driveshaft connects to the impeller, held in place by bearings on the pump. Watercraft operate on direct drive systems, meaning the impeller spins whenever the engine is running.

This concept often confuses new riders who expect motion to stop when in neutral, similar to a boat.

Jet drive systems lack a true neutral position.

It’s only putting the reverse bucket between forward and reverse. When it comes to jet drive boats, you want to turn the engine off when docked.

How the Steering Works

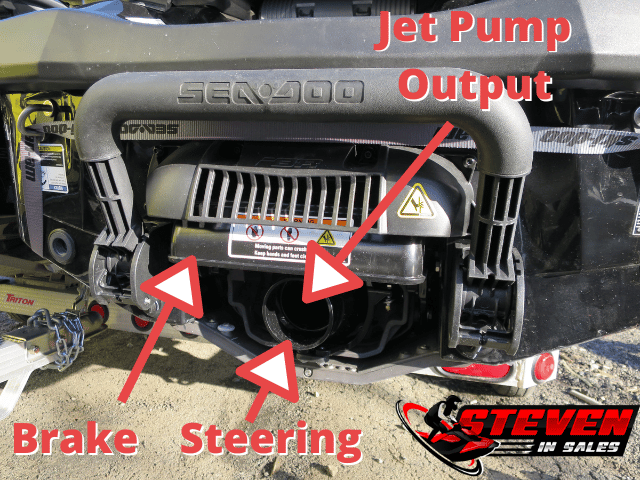

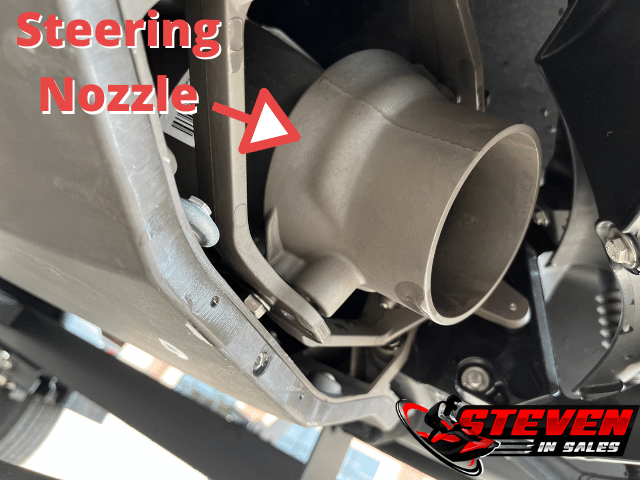

To control left and right movement, a steering nozzle is utilized.

The steering nozzle is simple: a metal cone that pivots and directs the water flow. Turning the handlebars to the right moves the nozzle right, directing the water flow accordingly.

Backing Up

New riders can find backing up in reverse to be confusing because it’s not the direction that many people think, but is easy to get used to.

No Hydraulics

Since you’re only moving a lightweight nozzle, hydraulics are unnecessary, unlike in a typical boat.

A long and stiff cable directs the nozzle.

Without hydraulic steering, you can freely move the handlebars when the engine is off without causing damage, as long as the nozzle isn’t obstructed.

You Can Trim The Craft

PWCs can feature trim, but not every model requires or includes it.

Unlike boats, PWCs position their pump intake forward, minimizing bow rise, rendering trim unnecessary, and often perceived as an optional feature by manufacturers (my opinion).

Trim proves beneficial in racing or tow sports, offering customizable adjustments to suit your needs.

Trim adjustment occurs at the steering nozzle. If your watercraft includes trim, it’s typically operated by an electric motor (all 4-strokes use electric trim), raising and lowering the nozzle. This nozzle not only controls left and right movements but also influences bow rise.

Not every model has trim, and the ones that don’t have it can’t always add it either. To be honest, trim is nice, but not a must-have if you don’t already have it.

How Reverse Works

The reverse bucket, as its name implies, facilitates movement in the reverse direction and serves as a braking mechanism in certain models.

In a jet ski’s direct drive system, forward motion is constant. To engage reverse, the bucket drops, redirecting water to propel the craft backward.

Channels within the reverse bucket assist in left or right turning while reversing.

Reverse Bucket Is The Brake

The reverse bucket doubles as a brake, but only electronic reverse units have brakes.

Manual reverse lever models should never be pulled above idle, as it can damage the reverse bucket.

Braking and reverse are basically the same thing.

The Bailer Tubes keep you Afloat

Bailer tubes utilize the suction created by the pump to remove any water that may be in the hull.

The pump generates a negative vacuum, and with small hoses bent in the right way, you have a simple bilge pump.

The downside is that the bailer tubes only work when the engine is on, but you can learn more about bailer tubes here.

The Intake Grate Takes In The Water

The intake grate is not attached to the jet pump but is needed for the jet pump to work properly.

The intake grate is to help focus water into the pump and keep large objects from getting in and damaging the pump.

A common misconception I see about the intake grate is that people want to remove right away when they suck something up…

DO NOT DO THIS!

The intake grate is typically through bolted, making it difficult to remove all the bolts.

Additionally, if you do remove it, you’ll need to seal it back up and wait 24 hours for it to dry. Therefore, it’s best to avoid removing it whenever possible.

Jet Pump Vs Propeller

Jet pumps and outdrive/outboards or anything that uses a propeller both have their advantages and disadvantages.

To better understand each, I’m going to list the pros and cons of a jet drive.

Pros:

- No exposed prop, no spinning blades out in the open like you have with normal boats. I find this as a huge plus, especially if you have kids.

- Finer grain control, the pump is always processing water and pushing it where it needs to go, which gives you far greater control over the boat.

- Brakes – Brakes are not a thing on normal boats, but a thing on some jet drive boats.

- Jet drive boats can float in shallower water as there is no lower hanging unit.

- You don’t have to worry about trim as much as jet drive engines take in water closer to the center of the boat, so less bow rise.

- Jet drive systems are simpler and have fewer moving parts than other boat’s drive systems. This also means less maintenance on a jet drive system compared to other boats.

Cons:

- A jet drive is basically a large vacuum and will suck up anything that gets in the way. That means ropes, rocks, sticks and so on. The wear ring is made to protect the pump, but things happen. And no, you can’t put a screen over the intake.

- Jet drive engines tend to use more gas than a normal boat, though it’s not much more, and all boats suck at gas mileage. It’s less noticeable on waverunners because they’re smaller.

- While jet drive boats can float in shallower water, you still can only start your machine in 3 feet of water. The pump is a powerful vacuum that will suck up anything too close to it, and that goes for sand and rocks on the water floor.

NOT A Jet-Engine!

A few people mistakenly believe that a watercraft engine operates similarly to a jet engine seen on planes.

Prominent boating magazines refer to jet drive engines as “jet engines,” which is incorrect and quite annoying.

It gets even more confusing when people conflate the Rotax engine used in planes with the Rotax engine used in Sea-Doo’s.

Rotax is own by BRP, who also own Sea-Doo, but the engines are very different.

The jet pump engine in boats are not the same as jet engines on planes.